Products

Blade for Engo Ice Resurfacer

1.Engineered to Fit Engo-Type Machines

This blade is designed to align with common bolt patterns found on Engo ice resurfacers, offering a smooth installation with no adjustments needed.

2.Precision-Ground for Even Ice Finish

Each blade is CNC-finished to maintain a straight, uniform edge—reducing chatter and delivering consistent ice quality across the full pass.

3.Made from Durable High-Carbon Steel

Built to handle repeated resurfacing cycles, the blade holds its edge longer and resists deformation under rink-level pressure.

4.Available in Multiple Lengths

Standard 77” and 88” lengths available to match different Engo-type models, including compact and full-width machines.

5.Supports Custom Specifications

Whether you need special hole spacing, a unique bevel, or rust-resistant coating, we can produce the blade to fit your machine’s exact requirements.

Features

Engo® Ice Resurfacer Blade Overview

For ice arenas using Engo®-type resurfacers, SHJ KNIFE offers a high-performance 88-inch scraper blade designed to meet the demands of modern, electric-powered machines. Whether your rink runs an Icewolf, Minimag, or Colibri model, our blades are built to deliver a consistently smooth cut across the entire ice surface.

Each Engo-compatible blade is precision-machined to match the mounting specs and cutting geometry of your equipment. Whether you're resurfacing a full-size competition rink or a multi-use training facility, this blade is built to perform-pass after pass, week after week.

Size & Specifications

|

Material |

GCr15 / Q235B |

|

Hardness |

60-62 HRC |

|

Size |

2.000 / 2.150 / 2.300 mm |

|

Tolerance |

L: ±1mm; W: ±1mm; Th: ±0.1mm |

Key Benefits of Engo-Compatible Blades

1.Made for Electric Rink Machines

Designed with lightweight resurfacing systems in mind, these blades balance sharpness with structural flexibility-ideal for Engo-style units.··

2.Consistent Ice Finishes

CNC-ground to exact specifications, our scraper knives produce a level, even surface with minimal effort.

3.Longer Blade Life

Heat-treated high-carbon steel helps resist wear, letting you resurface longer between replacements.

4.Quick, Reliable Installation

Each blade is made to fit common Engo mounting systems, reducing downtime and simplifying maintenance.

5.Customization Ready

Have a non-standard configuration? We can tailor the length, hole pattern, and edge profile to your needs.

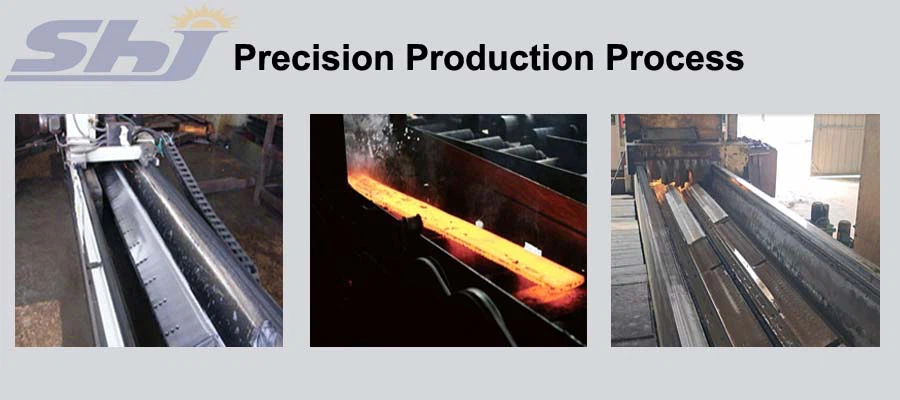

How We Make Each Ice Resurfacing Knife

It all starts with raw high-carbon steel chosen for strength and edge retention. After blanking and flattening, each blade is ground to the correct thickness and mechanically straightened to prevent warping.

Next, the blade goes through controlled heat treatment to improve durability and edge stability. Mounting holes are then drilled using CNC machines for perfect alignment with Engo-style resurfacers. Finally, the cutting edge is sharpened to a clean, consistent profile ready for rink use.

--Material Selection & Blanking

We begin with high-carbon or alloy steel selected for its edge stability and resistance to wear. Steel sheets are cut into exact-sized blanks, forming the foundation for every blade.

--Rolling & Surface Grinding

Each blank is rolled to the proper thickness and surface-ground to ensure it's perfectly flat. This step lays the groundwork for accurate cutting angles later in the process.

--Straightening for Flatness

No blade leaves our facility warped. We mechanically straighten every piece to make sure it sits flush during installation and delivers a clean, even cut.

--Heat Treatment

This is where strength meets science. Our controlled heat treatment process boosts hardness and prolongs edge life, so your blade holds up under repeated use.

--CNC Drilling & Edge Sharpening

We drill every mounting hole using CNC machines for precise alignment with Olympia® machines. Then we sharpen the edge using fine grinding to achieve a smooth, clean cutting surface that's rink-ready from day one.

Blade Quality Checks

Before leaving our facility, every Engo-compatible ice scraper blade goes through a full inspection process. We measure dimensional tolerances, confirm hole placement, and conduct Rockwell hardness testing (typically HRC 60–62) to ensure the steel will hold up under real rink conditions.

Each blade also undergoes pressure simulation to mimic actual resurfacing loads, helping us catch surface defects or material inconsistencies before shipment. Final visual inspection is done piece by piece-no batch sampling, just full control from start to finish.

Packaging & Shipping

We know your blades need to arrive sharp and protected. That's why every scraper knife is wrapped in edge guards, sealed with anti-corrosion film, and packed in reinforced crates designed for export.

Whether you're ordering one set or a full shipment, we prepare all packaging to withstand long-haul transit. We also support custom pallet sizes, barcoding, and export labeling based on your receiving warehouse's needs. Global delivery options are available via air or sea.

OEM & Customization Services

If your Engo-style machine has a unique layout or size requirement, we can help. SHJ KNIFE supports full blade customization-from length and bolt patterns to edge angle and anti-rust coatings. Whether you're matching an older unit or trying a modified setup, we'll work with you to get the perfect fit.

Need a large-volume order with consistent specs? We also produce serialized batches for OEM-level customers and professional rink operators. Just send us your requirements-we'll handle the rest.

Looking for something beyond the standard? We also offer optional anti-corrosion coatings, edge treatments, and even custom branding if you want your blades to match your rink's identity. Whatever your spec sheet looks like, our team can turn it into a finished product-accurate, repeatable, and built to last. Just send us your drawing or a sample blade, and we'll take it from there.

Olympia® Ice Resurfacing Blades

1. What machines do your blades fit?

Our 88-inch blades are compatible with many Engo-type ice resurfacing machines, including Icewolf, Minimag, and similar models. Not sure about the fit? Let us know your bolt layout or previous blade spec.

2. Can I get a custom blade size?

Yes. We support custom lengths, hole positions, and cutting angles. Just provide your required measurements or a blade sample.

3. How long does the blade typically last?

That depends on your rink's usage and maintenance, but most customers report excellent edge retention due to our heat-treated steel and precision sharpening.

4. Are these blades pre-sharpened?

Yes. All Engo-compatible blades come ready to install, with a clean edge already ground in during final processing.

5. How are the blades shipped?

We use moisture-resistant packaging and heavy-duty crates designed for export. Orders are shipped worldwide with tracking and proper documentation.

Disclaimer & Trademark Note

Disclaimer: All brand names, including Zamboni®, Olympia®, and others mentioned, are registered trademarks of their respective owners. Our ice resurfacing blades are third-party replacement parts designed to be compatible with these machines. These blades are not manufactured or endorsed by the original equipment manufacturers, and the use of these brand names is for compatibility reference purposes only.

Hot Tags: blade for engo ice resurfacer, blade for engo ice resurfacer suppliers, manufacturers, factory

You Might Also Like

Send Inquiry