Products

Ice Resurfacer Blade – Compatible with Zamboni 552AC

1. Precision Fit for 552AC

Engineered to match Zamboni Model 552AC mounting specs with no modifications needed.

2. Durable Carbon Steel Blade

Manufactured from high-strength carbon steel for long-term wear resistance.

3. Smooth, Even Resurfacing

Accurately ground edge delivers consistent ice depth and a clean surface.

4. Easy to Install & Replace

Standardized hole pattern and flatness make swap-outs fast and efficient.

5. Custom Options Available

Blade thickness, edge profile, and drilling can be tailored to your needs.

Features

About Ice Resurfacer Blade – Compatible with Zamboni 552AC

The Ice Resurfacer Blade – Compatible With Zamboni 552AC is built to meet the demands of modern electric resurfacing machines. Designed specifically for the Zamboni® 552AC model, this high-precision blade delivers clean, even cuts with every pass, helping maintain a smooth, professional-grade ice surface.

At SHJ KNIFE, we specialize in manufacturing ice resurfacing blades with exacting standards. Our blades are crafted from premium carbon steel and processed for long-lasting edge sharpness, consistent performance, and easy replacement. Whether you're operating a municipal rink, training center, or professional facility, our 552AC-compatible blade provides the reliability you need to keep your resurfacer running at its best.

Size & Specifications

We offer ice resurfacer blades in standard sizes, including 77-inch and 84-inch options, widely used in both recreational and professional ice resurfacing equipment. Each blade is manufactured to strict dimensional tolerances to ensure a precise fit and consistent performance.

| S/N | Product | Dimension | Material | |

| 1 | Zamboni® 77" UNC Knife | 1955.8×127×12.6MM | Knife body: Q235B; Edge: CrWMn | |

| 2 | Zamboni® 86" UNC Knife | 2185×127×12.7MM | Knife body: Q235B; Edge: CrWMn | |

| 3 | Zamboni® 96" UNC Knife | 2438.4×127×12.7MM | Knife body: Q235B; Edge: CrWMn | |

Custom sizes are also available upon request. We support modifications to hole spacing, quantity, and layout, making our custom scraper blades compatible with a variety of machine models. Detailed specification sheets, including blade length, thickness, hole pitch, and weight, are available for download. Technical drawings (PDF format) can be provided to assist with equipment matching or engineering approval.

Key Features of Our Zamboni®-Compatible Blades

-

1. High-Quality Steel Construction

Made from high-carbon steel for strength and long-lasting performance.2. Direct Replacement for Zamboni® 650

Perfectly designed to replace the original blade, ensuring easy installation.3. CNC Precision Grinding

Achieves optimal sharpness and performance with exacting tolerances.4. Available for Customization

Tailor the blade to your resurfacing machine with size and hole pattern options.5. Proven Reliability

Tested to maintain smooth, flawless resurfacing under rigorous rink conditions.

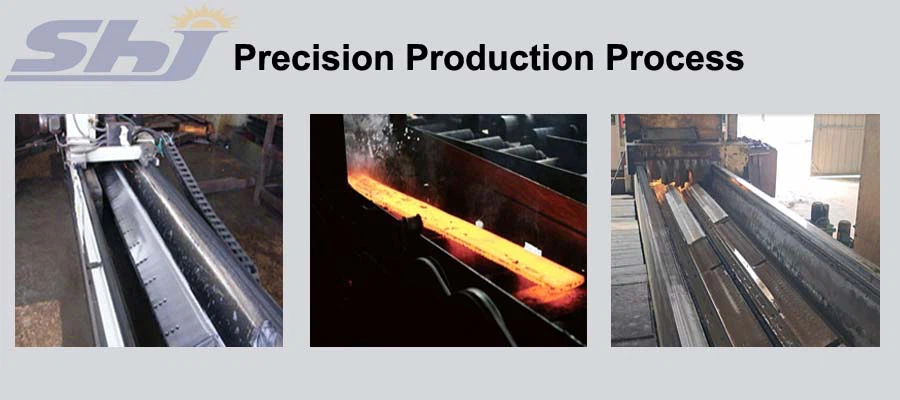

Precision Production Process

Each Zamboni®-compatible blade is crafted at SHJ KNIFE's ISO-certified facility with strict process control from start to finish. Our precision manufacturing ensures consistent quality with every blade:

--Material Preparation & Blanking

We begin with high-carbon or alloy steel, selected for its toughness. Steel sheets are cut into precise blanks using industrial shearing and rolling techniques.

--Rolling & Coarse Grinding

The blanks are then rolled to the desired thickness and surface-ground to remove excess material while maintaining flatness.

--Straightening for Dimensional Accuracy

Our technicians perform mechanical straightening to eliminate warping and ensure uniform blade geometry.

--Heat Treatment for Hardness

Blades undergo a controlled heat treatment cycle to optimize hardness and durability, essential for extended ice resurfacing performance.

--Drilling & Final Sharpening

Mounting holes are drilled with CNC accuracy. The edges are then sharpened using fine grinding to achieve a clean, consistent cutting surface.

Rigorous Quality Control for Ice Scraper Blades

To ensure each blade delivers peak performance on the ice, SHJ KNIFE enforces a strict quality control process at every production stage.

Our ISO-certified facility follows globally recognized quality protocols. Technicians perform optical comparator measurements to confirm dimensional accuracy and mounting compatibility across resurfacing machine types.

We conduct Rockwell hardness tests (HRC 60–62) on every batch to verify the blades meet the ideal balance of edge retention and structural toughness.

In addition, we simulate ice resurfacing pressure through load testing, helping us detect any micro-defects or inconsistencies before blades leave the factory.

Every blade is individually inspected-no random sampling. This ensures customers receive only consistent, ready-to-install scraper blades built for demanding rink environments.

Secure Packaging & Global Logistics

We know your blades need to arrive in perfect condition-sharp, clean, and ready for action. That's why we take packaging and shipping seriously.

Each ice scraper blade is carefully wrapped in protective sleeves to guard the edges, with anti-rust film added for moisture protection when needed. For bulk orders, we pack everything in sturdy wooden crates or heavy-duty cartons that can handle long-distance transport.

All of our export packaging meets international shipping standards, so you don't have to worry about customs delays or repacking issues. We work with reliable global carriers to ship worldwide by sea or air. Whether you're managing a rink in the U.S., Europe, or Asia, we'll make sure your order gets to you safely and on time.

Need specific labels, barcodes, or pallet sizes? Just let us know-we're happy to customize the packing to fit your warehouse needs.

OEM & Customization Services

We know that every rink has its own needs. That's why we offer OEM and customization services to help you get the exact ice scraper blades you need. Need a specific size, unique hole patterns, or a different edge shape? We can customize the blades to match your resurfacing machines perfectly. We're happy to work with you to get the fit just right.

Looking for additional features like anti-corrosion coatings or even a special color to match your rink's branding? We can do that too. Whether it's a small order or a large production run, we're ready to create high-quality blades that meet your exact requirements. And no matter what customization you choose, all our blades are built to last and perform just like our standard models.

FAQs About Ice Resurfacer Blades

1. Are your blades compatible with Zamboni® machines?

Our blades are designed to fit most commercial ice resurfacing machines, including Zamboni® and Olympia models. If you're unsure about compatibility, simply share your machine's model and specifications with us, and we'll confirm the fit.

2. What materials are your ice scraper blades made from?

We use high-carbon steel and alloy steels to manufacture our blades. These materials offer a strong balance of durability, edge retention, and flexibility for professional ice resurfacing.

3. How long do your blades last?

The lifespan of our blades depends on usage, but with our premium materials and precision manufacturing, our blades last longer than standard alternatives. Regular maintenance and sharpening will extend their performance.

4. Can I customize the size or features of my blades?

Yes! We offer full customization options. Whether you need a different size, hole pattern, or specific edge profile, we can tailor the blades to your exact requirements.

5. How do I maintain my ice scraper blades?

To ensure long-lasting performance, regularly check for signs of wear and sharpness. We recommend periodic sharpening and protecting the blades from excessive moisture, especially if you're not using the optional anti-corrosion coating.

Disclaimer & Trademark Note

Disclaimer: All brand names, including Zamboni®, Olympia®, and others mentioned, are registered trademarks of their respective owners. Our ice resurfacing blades are third-party replacement parts designed to be compatible with these machines. These blades are not manufactured or endorsed by the original equipment manufacturers, and the use of these brand names is for compatibility reference purposes only.

Hot Tags: ice resurfacer blade – compatible with zamboni 552ac, ice resurfacer blade – compatible with zamboni 552ac suppliers, manufacturers, factory

You Might Also Like

Send Inquiry